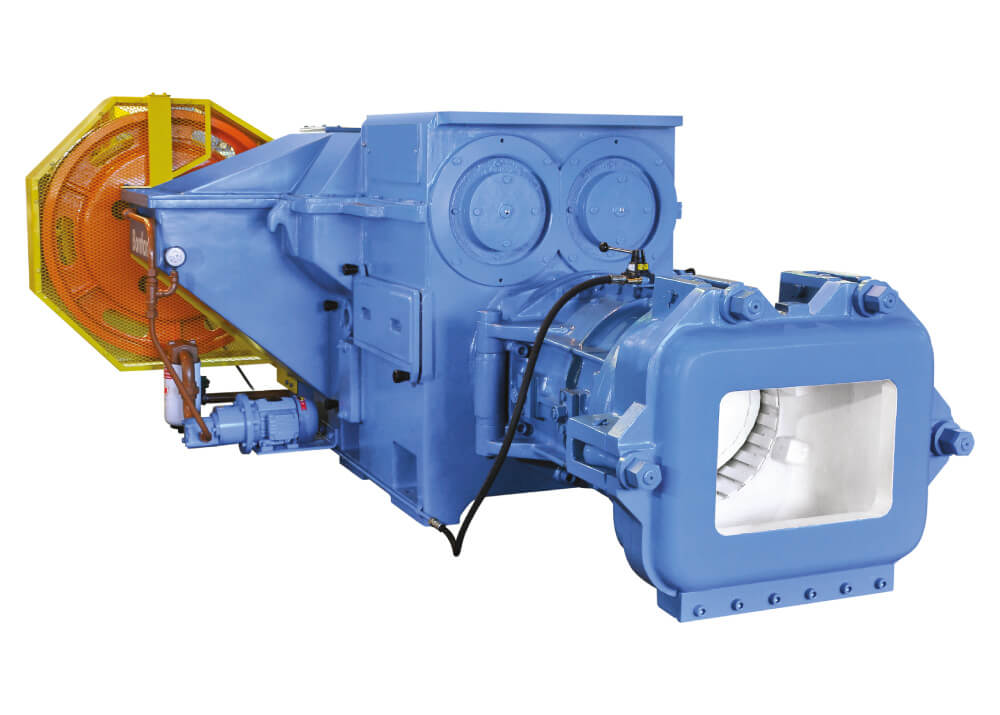

VACUUM MILL/EXTRUDER

The Monobloc Vacuum Mill/Extruder has as purpose to deaerate the clay paste deaeration so it becomes well compacted and with the final shape desired: solid and perforated bricks, flooring tiles, roofing panels for roof tile compression, etc. Equipment is sized to withstand heavy duty works.

Powerful pressers compress the clay, forcing it through two inclined and convergent grills. When the clay passes through the grills it undergoes the deaeration process. Just below the grills, a set of variable pitch coils performs the compaction and extrusion through the nozzle, which provides the final conformation to the product.

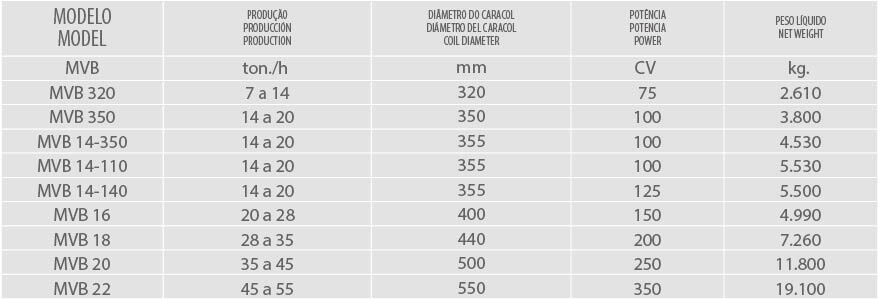

Note: Hourly productions are estimates and refer to wet material weight.

The above indicated productions refer to ideal working conditions, and may vary depending on the characteristics and grain size of processed clays.