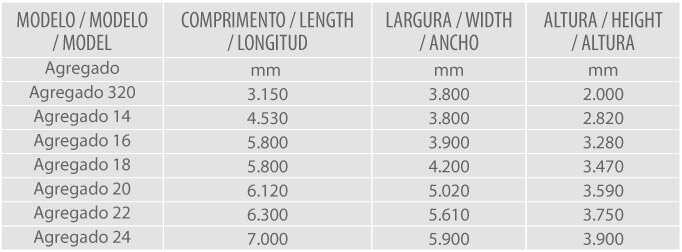

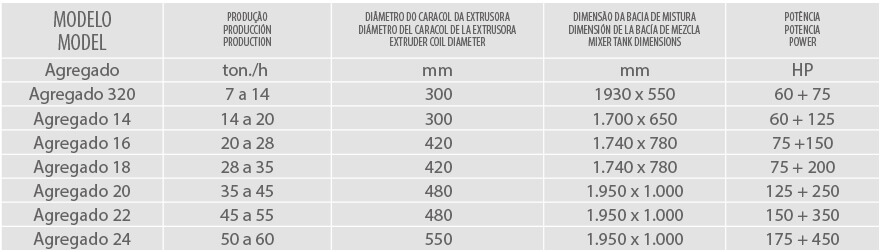

VACUUM AGGREGATE

The Vacuum Aggregate set adds a modern two-axis mixer and vacuum chamber at the top, to a robust extruder group at the bottom, which allows for the manufacture of more compact products, with lower moisture content, meaning shorter drying time and great finish.

The clay mixing, wetting and homogenization are performed in the mixer tank, which is achieved through its longitudinally arranged, double reduction-driven helical cutter head.

Properly prepared, the clay is conveyed to the upper coils, where it is pressed against vertical grills and spiral cutters, which break down the clay into small portions to be processed with excellent clay mass deaeration in the extruder connection chamber.

Without any contact with external air, the clay is compressed again by powerful extruder pressers, forcing it to undergo a second deaeration. Immediately below there, the raw material enters a variable pitch coil set, which extrudes it through the nozzle.

Note: Hourly productions are estimated and refer to the weight of wet material.

The productions indicated above refer to the ideal working conditions and may vary depending on the characteristics and granulometry of the processed clays.