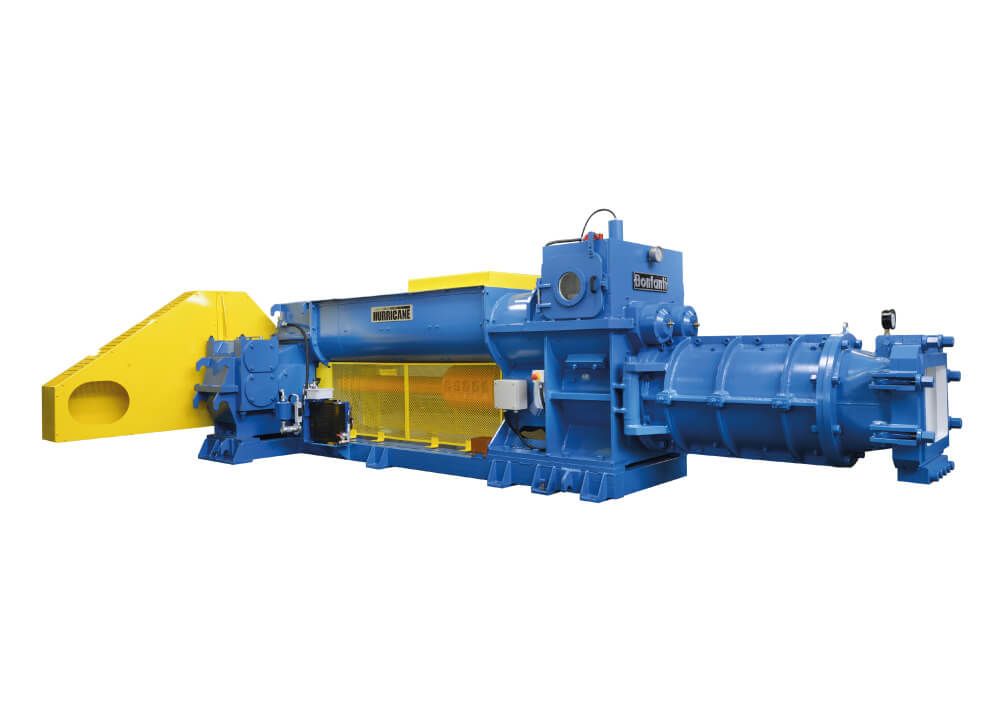

HURRICANE VACUUM MILL/EXTRUDER

Indicated to hard extrusion, that is, raw material having less moisture content, the Hurricane Vacuum Mill/Extruder performs clay paste deaeration so it becomes well compacted and with the final shape desired: solid and perforated bricks, flooring tiles and roofing panels for roof tile compression. This equipment includes a mixer tank that enables mixture and pre-compression of clay paste prior entering the vacuum chamber. It provides shorter drying time of manufactured products and an improved quality product.

With its three shafts driven by a single motor in synchronous operation, the equipment enables raw material processed to be introduced to a high efficiency mixer, starting the compression between the blades up to the pre-compression coils, thus compressing the material and forcing it through tapered front openings, forming a perfect airtightness and fractioning the material when it enters the vacuum chamber.

The fragmented raw material enters the vacuum chamber where it is deaerated, then pressers synchronized with the lower extrusion coil efficiently feed the extrusion area so the raw material passes through the nozzle, which is responsible for conformation of the ceramic product.

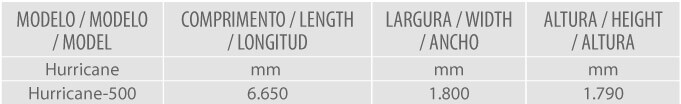

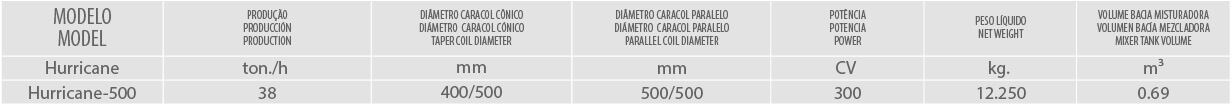

Note: Hourly productions are estimates and refer to wet material weight.

The above indicated productions refer to ideal working conditions, and may vary depending on the characteristics and grain size of processed clays.