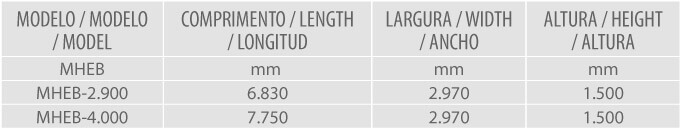

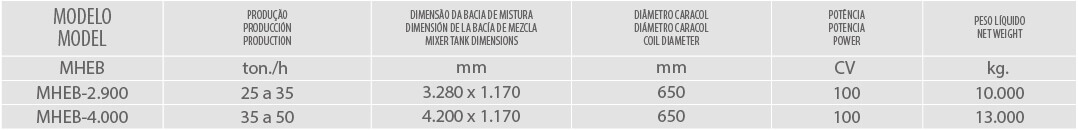

HORIZONTAL MIXER-EXTRUDER

A robust equipment, the Horizontal Mixer Extruder is indicated to mix, efficiently, several types of clays employed in the ceramics industry, also promoting moistening and homogenization of the paste; all in a single operation. This operation is useful for both the cured and pre-moistened clay and the clay that is moistened in the own mixer.

The clay mixing and moistening takes place by means of gradual displacement of the clay inside a mixer tank, provided with two horizontal shafts fitted with dual fixed blade rows, which are driven by a set of twin outlet gears. It is possible to change the inclination angle of the mixer blades, aiming to increase or reduce the clay mixing time in the mixer, thus changing the equipment yield according to the production line demands. After the mixer blades, there are compression coils that extrude the clay, forcing it through a grill in order to eliminate the roots present in the mixture. At the end of the mixer shafts, there are spiral cutters that cut-off the clay clods, reducing its grain size.

Obs.: Las producciones horarias se estiman y se refieren al peso del material húmedo.

Las producciones indicadas anteriormente se refieren a condiciones ideales de trabajo, pudiendo sufrir variaciones dependiendo de las características y de la granulometría de las arcillas procesadas.