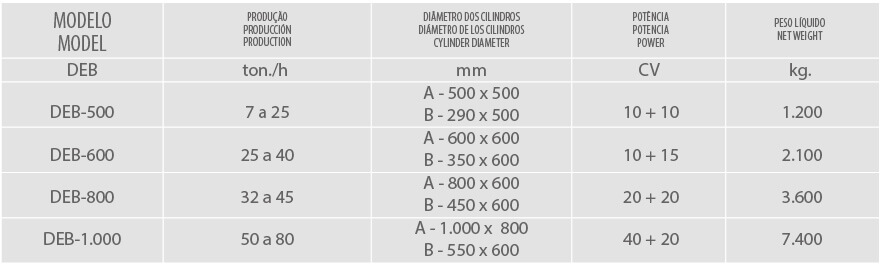

DISINTEGRATOR

Disintegrator is an equipment indicated to process natural clay with low moisture content, forming clods that are compact and very resistant to normal homogeneous action of the clay. Inside the Disintegrator, small foreign matters, eventually embedded in clay, are separated and a preliminary lamination is performed.

The Disintegrator consists of two cylinder assemblies, namely a larger flat cylinder (A), rotating at high speed to maintain a constant material feeding, and a cylinder (B) equipped with blades also rotating at high speed to break the harder clods, aiming to obtain a uniform material.

– Mounted on reinforced metallic structure;

– Replaceable flat cylinder with very hard surface and high abrasion resistance;

– Cylinder with replaceable, thermally treated and easy removal blades;

– Individual cylinder motorization;

– Coil spring system functioning as safety component, which opens if foreign matter enters between cylinders, and expels such matters afterwards;

– Accident risk areas protected in compliance with the safety standards (NR 12).

Note: Hourly productions are estimates and refer to wet material weight.

The above indicated productions refer to ideal working conditions, and may vary depending on the characteristics and grain size of processed clays.