The start of Bonfanti S/A dates back to the small foundry that Mr. Carlo Bonfanti founded in 1904 for the production of vehicles of that time.

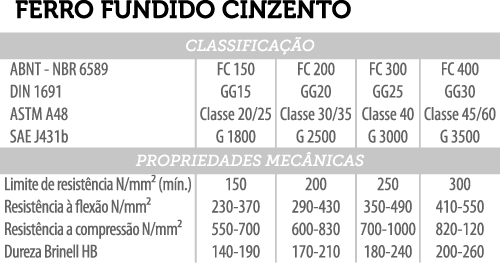

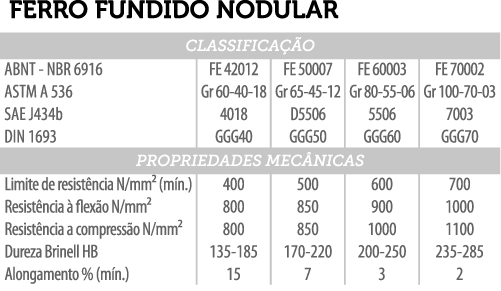

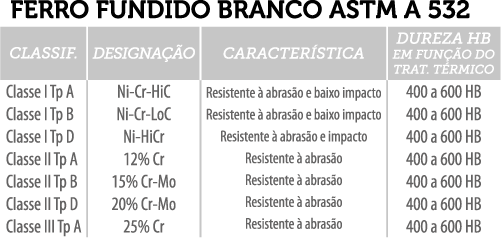

To this day, the Bonfanti foundry specializes in cold cured resin manual molding of cast iron and medium and large low-alloy steel parts.

In addition to equipment parts manufactured by Bonfanti itself, the foundry offers custom parts for all market segments.

We have two induction furnaces, sand recovery system, continuous mixers, cranes for up to 15 ton, as well as chemical, metallographic and sand laboratories.

Bonfanti castings can be supplied with quality certificates such as mechanical testing, ultrasound, X-ray, etc.

Bonfanti has a modern machining park (CNC horizontal and vertical lathes, CNC broaching machines, CNC portal-machining centers, among others), thus being able to supply raw and / or machined castings.